What is Handmade?

Learn more about our products, our process, our designs, and our commitment to keeping it real.

Handmade with love, passion, and uncompromising quality.

Everything we make at Swift Leatherworks is built for a lifetime of faithful use. We use the highest quality leather, hardware, and materials we can find. We use “analog” tools like utility knives, rawhide mallets, and hole-punches. We set our rivets with hand-operated machines that don’t require electricity. We hand-stitch with steel harness needles and waxed thread. It’s true that we’re saving up for a professional-grade sewing machine, however, the last time I checked, sewing machines still need to be operated by hand. But all that aside, the assembly process is really just one small piece of a much larger puzzle.

The real work starts long before the first cut

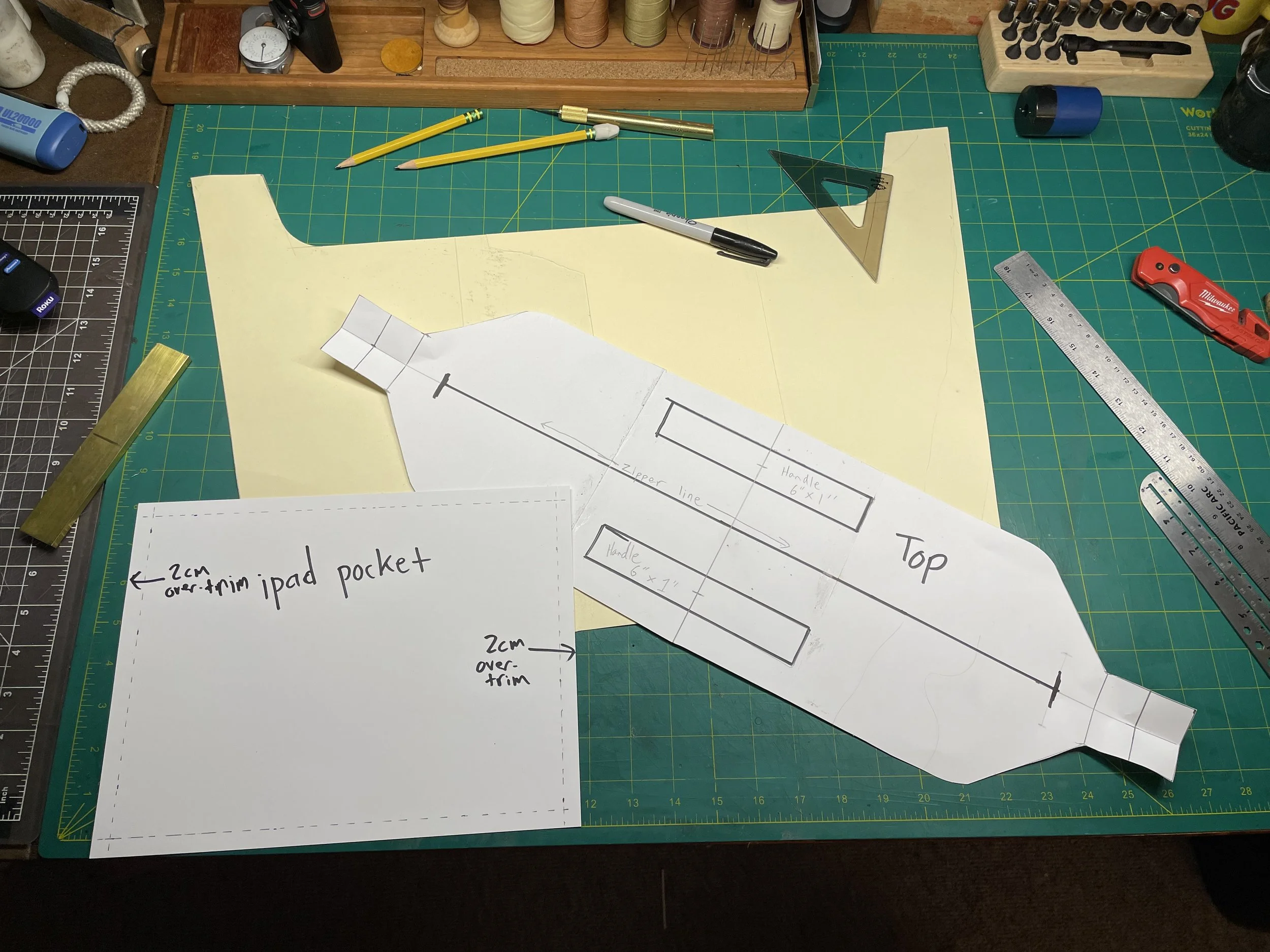

The most challenging part of our work starts long before we cut into that first piece of leather. Every project starts with ideas, thoughts, and feelings. Then we pick up a pencil and a notebook and start drafting ideas. We make drawings, mock-ups, and paper patterns. We transfer the paper patterns onto manila folders, cut them out, and then stick them together with masking tape to make sure everything fits. If something doesn’t look right, we go back to the drawing board. If something doesn’t feel right, we go back even further. If the mock-ups look good, then we make a prototype. Then we look for ways that we can improve on the prototype.

We draw, design, pattern, and prototype everything we make

Once we get a solid prototype, we hand cut a “permanent” pattern out of heavy gauge pattern paper. Then we trace the pattern onto a piece of leather, cut it, glue it, punch it, stitch it, finish it, and then review the finished product. Then we choose a different leather and replicate the process. Then we do it again and again until we finally land on the core version of the product. From there, we iterate even more, experimenting with different thread colors and thicknesses, different hardware, different proportions, different vibes.

The process of creating a new product is time-consuming, difficult, expensive, and totally worth it. This process is what makes our designs truly unique. Even if we start with someone else’s pattern, by the end of the build process, the finished product is truly ours. We don’t chase trends or copy the most popular leathergram influencers. We make vintage-inspired leather products that WE love, and hope that other people will love them too. We don’t sell hundreds of units, we don’t make thousands of dollars, but we make good products, with great materials, and we use build techniques that ensure that our products will last a really, really long time. So when we say, “handmade leather goods,” we mean it.

A commitment to keeping it real.

At Swift Leatherworks, we don’t cut corners on quality so that we can make our products more profitable. We don’t cheap-out on materials and then boost our prices to pay for relentless marketing. We don’t outsource or import our products, and we never, ever plan for our items to fall apart so you will buy them again sooner.

We don’t use cheap plated hardware to make our bags look fancier. We don’t use cardboard interfacing to make our bags look stronger. We don’t use PVC coated, pigmented, or painted leather to make our bags look more “authentic.” We don’t use plastic, PU, or PVC, and we never use synthetic. Why? Because at Swift Leatherworks, we keep it real.